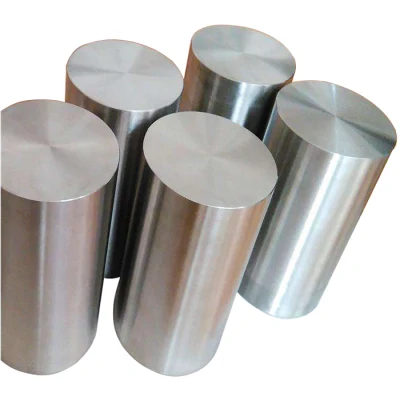

Titanium Sheet Gr1/Gr2/Gr5/Gr7/Gr11/Gr12

Titanium sheet 1. Material: Titanium and titanium alloy 2. Grade: TA1,TA2,TA8,TA9,TA10,TC4,Gr1,Gr2,Gr3,Gr5,Gr12,Gr16,Gr7

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | GR1/GR2/GR5/GR7/GR11/GR12 |

| Length | 100-12000mm |

| Thickness | 0.5-60mm |

| Transport Package | Export Standard Seaworthy Packing |

| Specification | EN, GB, ASTM, AISI, JIS, DIN |

| Trademark | Oubaige |

| Origin | Tianjin, China |

| Production Capacity | 600 Tons/Month |

Product Description

Titanium sheet1. Material: Titanium and titanium alloy

2. Grade: TA1,TA2,TA8,TA9,TA10,TC4,Gr1,Gr2,Gr3,Gr5,Gr12,Gr16,Gr7

3. Size: T 0.5-5.0mm x W2000mm x L 12000mm

4. Standard: GB/T 3621-2007,ASTM B265,ASTM F67, ASTM F136

5. Supply status: R or M or Y

6. Surface treatment: Pickling, sand blasting, polishing

7. Application: Aircraft manufacturing, aerospace industry, mechanical manufacturing, spectacle frames, golf clubs, super sport bicycles, titanium artificial bones, military, chemical, pharmaceutical, medical, etc.

Pls feel free to contact us for more information. Welcome any inquiry.

More production perfermance and advantages

1. Low Density and High Specificate Strength

2. Excellent Corrosion Resistance

3. Good resistance to effect of heat

4. Excellent Bearing to cryogenic property

5. Nonmagnetic and Non-toxic

6. Good thermal properties

7. Low Modulus of Elasticity

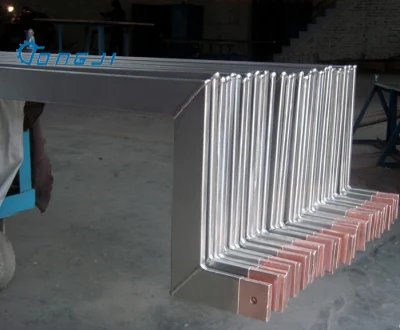

Production technology

Titanium sponge--------smelted to titanium--------raw material testing ----- heating when forging------- rolling------- peeling ------------straighten---------grinding---------ultrasonc flaw detection--------packing

| N | C | H | Fe | 0 | Al | V | Pa | Mo | Ni | Ti | |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.20 | 0.18 | / | / | / | / | / | bal |

| Gr 2 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | / | / | bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.30 | 0.35 | / | / | / | / | / | bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.50 | 0.40 | / | / | / | / | / | bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.40 | 0.20 | 5.5~6.75 | 3.5~4.5 | / | / | / | bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | 0.12~0.25 | / | / | bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5~3.5 | 2.0~3.0 | / | / | / | bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.30 | 0.25 | / | / | / | 0.2~0.4 | 0.6~0.9 | bal |

| GR5eli | 0.03 | 0.08 | 0.012 | 0.25 | 0.13 | 5.5~6.5 | 3.5~4.5 |

| Grade | Tensile strength(min) | Yield strength(min) | Elongation(%) | ||

| ksi | MPa | Ksi | MPa | ||

| 1 | 35 | 240 | 20 | 138 | 24 |

| 2 | 50 | 345 | 40 | 275 | 20 |

| 3 | 65 | 450 | 55 | 380 | 18 |

| 4 | 80 | 550 | 70 | 483 | 15 |

| 5 | 130 | 895 | 120 | 828 | 10 |

| 7 | 50 | 345 | 40 | 275 | 20 |

| 9 | 90 | 620 | 70 | 438 | 15 |

| 12 | 70 | 438 | 50 | 345 | 18 |

| 23 | 860 | 795 | 825 | 760 | 8 |