Al

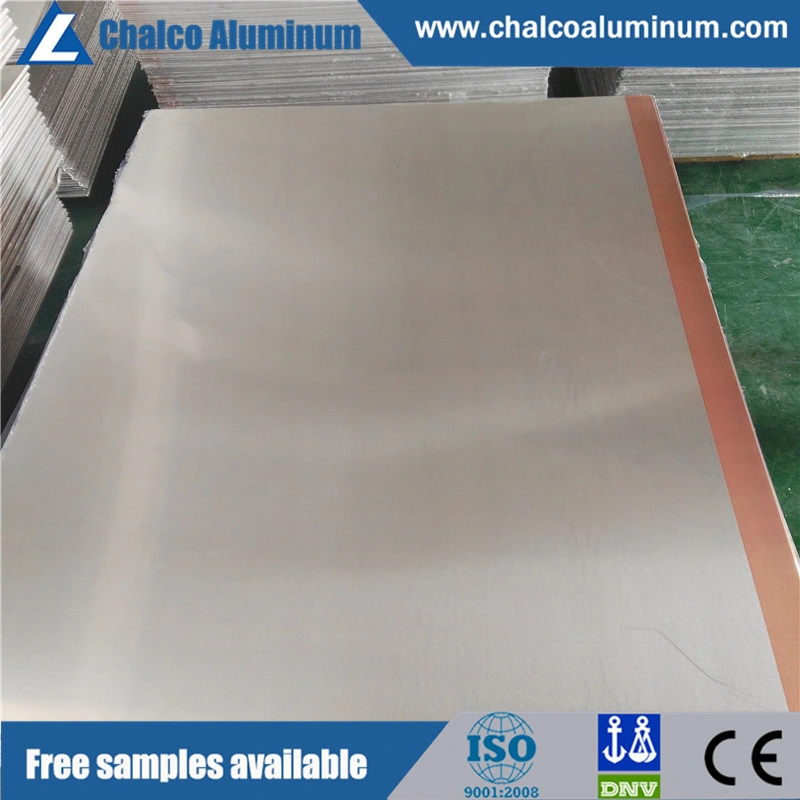

Al-Cu Clad Plate Sheet Transition Joints Cu and Al are both good conductors of electricity and materials for making elec

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | 1050, 1060, 1070, 3003, 8011/T2 |

| Peeling Strength(N/mm) | More Than 12 |

| Technique | Explosive Welding |

| Tensile Strength(N/mm2) | More Than 120 |

| Density(g/cm3) | 3.5-3.9 |

| Transport Package | Export Standard Wooden Case |

| Specification | According to Customer Requirement |

| Trademark | Chalco Aluminum |

| Origin | Henan China |

| HS Code | 7419999100 |

| Production Capacity | 10000mt/Month |

Product Description

Al-Cu Clad Plate Sheet Transition JointsCu and Al are both good conductors of electricity and materials for making electric conductors. Cu reserves are few, output is less, processing is more difficult and price is higher. Al is the opposite, and in many cases, Cu is replaced by Al in the power industry. The substitution of Al for Cu is an important technical measure for the development of the power industry.

The oxide film on the Al surface is very strong and the electrical resistivity is very high. Mechanical connections between Al and Cu are unreliable, and explosive welding is needed to reduce resistance and power consumption and accidents between them.

The melting points of Al and Cu are quite different.Al is oxidized strongly at high temperature, which is easy to form intermetallic compounds such as AlCu2. Therefore, fusion welding between Cu and Al is rather difficult.

The melting points of Al and Cu are quite different. Al is oxidized strongly at high temperature, which is easy to form intermetallic compounds such as AlCu2. Therefore, fusion welding between Cu and Al is rather difficult.

In comparison, explosive welding, with its unique advantages, can play an important role in the production of large area and arbitrary thickness ratio of Al-Cu composites.

Characteristics of explosive welding of Al-Cu Clad Plate Sheet Transition Joints:

1. the joint has good corrosion resistance, reliable and stable electrical properties.

2. the mechanical property and resistance value of the joint are good.

3. the joint has good electrical conductivity and is a rare structural material in the electric, electronic and electrochemical industries.

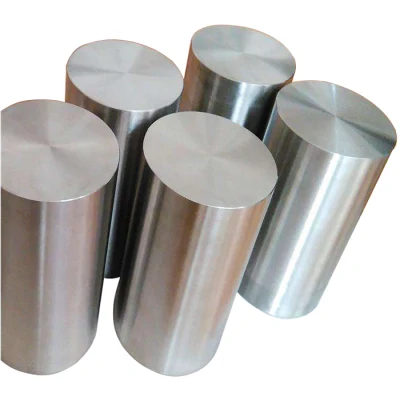

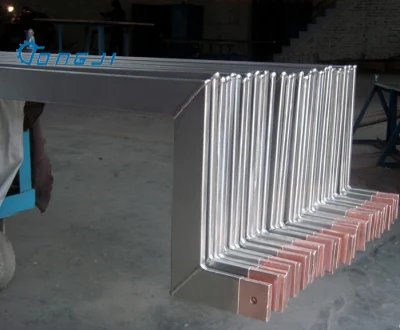

Explosively welded Al-Cu composites are usually used to fabricate transition electrical joints in the form of plates, tubes or bars. Explosive welding of Al-Cu transition joints is simple and can be used to weld flat, tubular and axisymmetrical parts. These parts have strong working ability.

Intermediate compounds of Al 2Cu with transverse cracks were found on the joint surface of Al-Cu composite pipe, Cu as inner tube and Al as outer tube. Compared with the matrix, the hardness of the compound increased obviously. In addition, the strengthening of the substrate after deformation is obvious. The Al-Cu composite pipe is used for the terminals of the high voltage distribution station.

One of the greatest advantages of the conductive busbar connector is the small contact resistance of Cu and the low cost of Al. The explosive method can be permanently combined into a continuous conductor.

Al-Cu clad plate is used as a transition joint in the production line equipment of Al alloy profile surface treatment after machining. On this device, the Al side is welded with the Al conductive beam, and the Cu side contacts with the Cu Cu base. Contact surfaces are cooled by tap water. The contact surface of this structure will not be overheated and arc-drawn, and the conductive performance is stable, which improves the quality of Al surface treatment; avoids heating and reduces power consumption; the life of the conductive plate is prolonged, the number of maintenance and replacement is reduced, and the price is low, which is only 1/4 of the same kind of foreign products. Al surface treatment and large electroplating production equipment has a wide range of applications.

| Base material | 1050,1060,1070, 3003, 8011 |

| Cladding material | T2 |

| Standard | GBT 32468-2015 |

| Thickness | 0.1--14.5mm |

| Width | ≤1200 |

| Length | ≤6000mm |

| Cu coating thickness K % | 8~30 |

| Temper | O, H24, H18 |