Forming Heads by Hot Press

Hokkai Provided Hemispherical head to our clients with heavy wall thickness for oil&gas industry equipments There are lo

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | HHA |

| Dia | 3200mm |

| Transport Package | Steel Frame |

| Specification | HHA3015*53mm |

| Trademark | hokkai |

| Origin | China |

| HS Code | 73269019 |

| Production Capacity | 1000ton Per Month |

Product Description

Hokkai Provided Hemispherical head to our clients with heavy wall thickness for oil&gas industry equipments

There are lots of requirements for this dished head included material plates, formings and tolerance.

The dished heads specification as the follow

HHA ID3015*MIN (50+3MM), CUT BACK 150MM

Material requriment

1, the supplier shall guarantee that the plates suppllied are free of cavity, lamination and cracking, and without any defects

2, no weld repair shall be permitted

3, the vendor shall guarantee the commodities furnished are the new ones

4, gengeal requirements of base metal shall conform to applicable requirements of ASME SA-20, and clading plates shall conform to applicable requirements of

ASME SA-480

5, The base plates of SA516GR70 shall be ultrasonically examined in accordance with A-579 level A, Supplementary requirements S1

6, The cladding metal and the base metal shall be heat treat per individual material specification before bonding. the heat treatment (simulated pwht of mechanical test oupons) for the cladding plates after bonding shall be as follows

heat treatment 1 cycle

Holding temperature 510+/-28degree

cooling rate max 56 degree/hr

holding time : min10hr

7,The minimum shear strength of the cladding plates shall be 20,000PSI(140MPA),Shear strength test shall be made in the manner indicated in ASME SA-264 FIG.1

For formed hemispherical head

1, the formed hemispherical head shall be spun or pressed form blanks of sufficient thickness to achieve at least the minimum thickness.

2, the vendor shall guarantee the formed hemispherical head are the new one.

3,each head in welding bevel edge shall be 100% magnetic=particle examination to avoid flaws,cracks,laminatons or others defects.

4, welding groove shall be shaped to the final welding geometry and 100% magmetic particle examination for defects.

5, tolerance for formed hemispherical head shall conform to UG-81,ASME Code section Viii-1, although the following tolerance as shown in drawing, are not

covered by the code and shall be adhered to by the supplier

6, inside and outside surface of formed hemispherical heads before shipment shall be cleaned,dry and free of scale

1, Hokkai Group

2,YIXING HOKKAI

* Established in Mar 1994

* Start to produce in Oct 1995

* Became 100% Japanese owed in Aug 2000

* Purpose: Based on the HIW accumulative head plates experience for kinds of industries, service to the development of chinese industry

* Investor: Hokkai Iron Works 89.9%, Hokkai Limited 10.1%

* Total investment: USD26.3million; registered captial: 12million

3, YIXING HOKKAI DISHED ENDS ORDER PROCESS

4, YIXING HOKKAI PRODUCTION PROCESS

5, YIXING HOKKAI QC SYSTEM

Related Products

-

![High Quality Large Diameter SA516gr70 and SA240 304 Clad Dish Head]()

High Quality Large Diameter SA516gr70 and SA240 304 Clad Dish Head

-

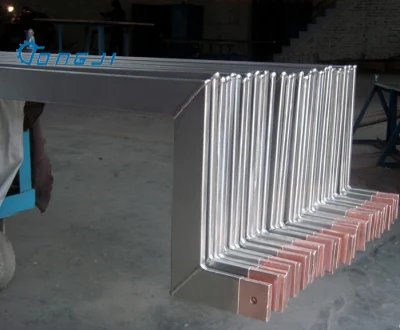

![OEM&ODM Titanium Clad Heat Exchanger Baffle Copper Tube Sheet]()

OEM&ODM Titanium Clad Heat Exchanger Baffle Copper Tube Sheet

-

![Hot/Cold Rolled ASTM Ss 304 304L 310S 316 316L 310S 430/Mirror/Galvanized/Aluminum/Carbon/Mild/Black/Color Coated/Copper/Titanium/Stainless Steel Sheet]()

Hot/Cold Rolled ASTM Ss 304 304L 310S 316 316L 310S 430/Mirror/Galvanized/Aluminum/Carbon/Mild/Black/Color Coated/Copper/Titanium/Stainless Steel Sheet

-

![PCB Industry Nickel Clad Stainless Steel Plate Excellent Welding Properties]()

PCB Industry Nickel Clad Stainless Steel Plate Excellent Welding Properties